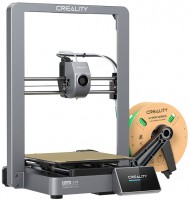

Flashforge Creator Pro

| Outdated Product $339.00 Print technology: deposition modeling (FDM/FFF); Filament material: ABS, PLA, TPU, PETG; 3D model file format: .stl, .gcode; Compatible software: ReplicatorG, Simplify3D, Makerbot Desktop, FlashPrint; Object dimensions (mm): 150x227x148; Object volume (L): 5; Min layer thickness (µm): 100 |

Flashforge Creator Pro | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Always clarify the specifications and configuration of the product with the online store manager before purchasing.

Catalog Flashforge 2025 - new arrivals, bestsellers, and the most relevant models Flashforge.

Omnivorous professional

The Flashforge Creator PRO 3D printer can be classified as a professional "printing machine". Thanks to the upgrade, the output quality of accurate printing is able to meet the needs of narrow profile specialists.

The device received a durable casing made of metal with plastic inserts. This solution of the case contributes to better thermal insulation, and the rigidity of the structure reduces the level of vibration, which negatively affects print quality. The accuracy of the assembly of working units and the adjustment of mechanisms, including the extruder, exclude model distortion and the formation of gaps between the layers.

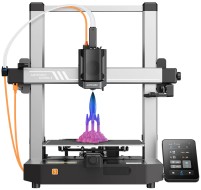

Print whatever you want

Modeling is carried out by the layer deposition method (FDM/FFF). You can combine the texture of the model, for example, using soluble HIPS plastic for one nozzle. The presence of two nozzles is also useful for models with small parts, as one can print the case, and the other can model small technical details of the product.

The extruder nozzles are 0.4 mm, but if you need to produce more precise and small elements, it is possible to install nozzles with a diameter of 0.2 and 0.3 mm.

Helpful advice! For better resolution and print quality, use nozzles with a smaller outlet diameter.

In order not to disturb the geometry of the created figure, an additional fan is located on the extruder, which blows the plastic during operation. Additional concentration of printing and accuracy of compliance with the parameters is provided by the close location of the printing mechanism to the nozzle. This is very noticeable when working with flexible plastic.

The versatility and convenience of the model lies in the fact that for printing you can use both common PLA, ABS, ABS +, PVA filaments, as well as more exotic materials: ELASTAN, HIPS, PLASTANPA, coPET, NYLON, PET, WOOD, PC, HDPE, Taulman, PBT. The use of such an assortment is possible due to the large temperature ranges of the heating elements (extruder up to 270°, working table up to 130°).

It is convenient to control the process and printing parameters using an informative LCD display, and the presence of a card reader allows you to work with the printer without additional wires. To better see how your model "grows", you can turn on the internal illumination.

To prepare a sample for printing, ReplicatorG, Simplify3D, Makerbot Desktop, FlashPrint software is used — utilities compatible with macOS, Windows, Linux operating systems.